Process – How a Saturated Solution of C60 Should be Prepared

Almost all of the current research that now exists out there regarding Carbon 60 has been derived from the original Baati / Paris original laboratory work. This involves a very precise & methodical set of instructions that must be adhered to throughout the manufacturing process in order to be left with a resultant preparation of C60 oil which meets a minimum saturation level of at least 0.8 mg of fullerene carbon 60 per 1 ml of oil. Learn more about how carbon 60 is manufactured here.

Steps as follows:

1)… Beginning with a pure 99.95% Fullerene C60

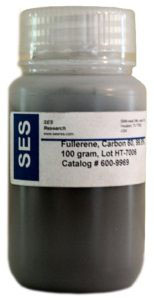

This can make or break the entire product, regardless of compliance with the original Baati / Paris protocol. The reason being is that the base C60 product is very expensive – typically being over $US 1200.00 for just 10 grams of C60 fullerene powder that has been processed to a 99.95% of purity (along with being oven dried to remove any remaining solvents from the manufacturing process). Unfortunately there are those out there using the cheaper & less pure Carbon 60 options – & without HPLC testing it is difficult to know exactly what one is purchasing. See our Lab Results here…

2)… Actual Manufacturing Process…

Again, as per the original Baati / Paris method, our C60 saturated oil products (olive oil, avocado oil & coconut oil options) all comply. As mentioned earlier, a saturated solution of C60 to have maximum efficacy when using as a supplement should be at a minimum of 0.8 mg of C60 per 1 ml of oil.

What is interesting to know is that the Carbon 60 element is VERY difficult to dissolve – being non soluble in water & slightly soluble in oil. What this means is that 5 – 6 times more carbon 60 needs to be added to a certain volume of oil than will actually dissolve (become permanently suspended) within solution in order to reach a maximum saturation.

All of our C60 oil preparations are mixed with a high speed mechanical stirring device for a period of two weeks (never less) in a sealed dark room until complete saturation is reached. At this stage depending upon the oil type, the oil will be purple in colour (especially if coconut oil as the oil is clear to begin with). As per the original Baati / Paris method the resultant oil is centrifuged to remove all non-suspended C60 particles with a large centrifuge at roughly 4000 – 5000 g for a period of 1 hour. Once this is done the resultant oil is then filtered through a 0.22 micron filter, glass bottled, sealed & then readied for shipping.

Let it be known that the actual process of making good quality C60 is not difficult – though sourcing a good quality fullerene C60 from the marketplace IS difficult, as we have found many suppliers to cut corners in the manufacturing process. The two main concerns are as follows;

A)… Sourcing a lesser purity C60 prior to manufacturing – The reason this often happens is due to the initial purchase price of the carbon 60. The purchase price from a reputable supplier (SES Research for example) can be anywhere between $US 800 – $US 2000 for a 10 gram bottle. As ONLY a 99.95% purity level that has been oven dried should be used for a preparation that will be consumed, less reputable suppliers will choose to use a lesser grade to begin with. The sad thing is that this is difficult to test for unless expensive HPLC equipment is used.

B)… Mixing time is often shortened for greater turnover – Even if beginning with an appropriate quality C60 product, cutting the mixing time short will lessen the concentration of the resultant oil. As per the original Baati / Paris study the ideal mixing time was 2 weeks (14 days), though what tends to happen with smaller manufacturing setups is that inventory may run out prior to a new batch being ready – hence cutting short the mixing time. Let it be known that C60 has very poor mixing / suspension qualities – thus requiring 14 days of continuous mixing.

It is important to note that without appropriate HPLC testing it will be near impossible to tell what you in fact do have from other suppliers – though when you have C60 suspended in coconut oil the product will have a purple colour, whereas with avocado & olive oil the resultant product will be more so a darkish brown.